C L O S E D S Y S T EMS

I N T R O DU C T I ON

Through leaks, spills, and ventilation, an “open” solvent-using system

will release solvent vapors directly into the laboratory environment.

This introduction may be reduced by adding several key components

to the typical system. These items are:

A properly sealed solvent reservoir with ventilation control

A solvent waste container with secure fluid connections

A carbon filter to reduce vapors escaping the waste

container

1A

SOLVENT RESERVOIR FLUID CONNECTIONS

For a closed system on a bottle, each container first requires a

bottle cap with ports to fit the specific tubing sizes. When using caps

with threaded ports for fittings, the fittings may be selected and

replaced to accommodate different diameters of tubes. Caps with

“slip-through” ports (non-threaded holes drilled or molded into a cap)

are acceptable, provided the holes fit the tubing sizes securely. Most

slip-through caps are made to accommodate 1/8” or 1/16” OD.

1B

SOLVENT RESERVOIR AIR INLET

In systems where sparging is not employed, to complete the closed

system on a bottle each container requires a device to control the

bottle cap vent. A closed bottle must function exactly like a coffee

travel mug -- liquid goes out through one hole, and air comes in

through a pinhole to displace the liquid removed. To manage the air

flow, the simplest answer is a check valve assembly made to occupy

a bottle cap port. The check valve allows air to enter a bottle as the

pump moves the liquid phase out to the system. It also minimizes

escape of vapors contained in the bottle. Should the bottle ever be

exposed to pressure -- a result of a rise in lab temperature (over

a warm weekend, for example) or a sparging line accidentally con-

nected -- to reduce the threat of explosion a check-and-relief valve

assembly is also available. The relief function allows pressure to

escape while still preserving a “pressure blanket” of 0.5-1psi in the

bottle. Although VapCheck

TM

units resist many standard solvents,

care should be taken to consider the chemical compatibility of a sol-

vent with VapCheck

TM

materials.

2A

WASTE CONTAINER FLUID CONNECTIONS

Many labs are standardizing on Justrite

®

2- and 5- gallon HPLC Cen-

tura

TM

waste containers. These safety cans have enough capacity

for days or weeks of typical flow, vent automatically at 5 psig if pres-

surized, and allow users to disengage waste lines and vapor filters

quickly during waste collection. Containers are available with either

Polypropylene or Stainless Steel quick disconnects. Care should

be taken when choosing the disconnect type. For example, at high

concentrations the solvent Hexane swells Polyproplyene as much

as 30%, causing the disconnect to “stick” and restrict fluid flow.

Containers and manifolds with stainless steel quick disconnects are

advised wherever such chemical compatiblity issues may arise; con-

sult a chemical compatibility guide before selecting a container. One

should also note that Justrite containers must be grounded while in

use and especially while emptying the container, as static electricity

has been known to ignite solvent fumes.

For labs which choose not to use Justrite

®

containers, Vaplock

TM

prod-

ucts are also available to adapt to standard drum and pail closures,

as well as Nalgene

®

83B, 53B, and 100-415 carboys. PLEASE NOTE

THAT IT IS NOT POSSIBLE TO GROUND DRUM, PAIL, GLASS BOTTLE

AND CARBOY (NON-JUSTRITE

®

) CONTAINERS; THIS MAY RESULT IN

A SAFETY HAZARD WITH FLAMMABLE SOLVENTS.

The type and dimension of waste tubing found on an HPLC varies

widely, depending on both system and user requirements. Outer

and inner diameters range from microns to inches, and tubing

material may be hard- or soft-wall plastic, metal, smooth-walled or

corrugated. All these lines must be connected to a waste container.

Adapting securely, without leaks and vapor release, poses a problem

when attempting a closed system. VapLock

TM

manifolds adapt to

tubing sizes up to 1/2” ID or OD (and larger if necessary) and can be

stacked to accept additional lines. Most manifold ports permit direct

connection of 1/4” or 1/2” threaded NPT fittings.

2B

WASTE CONTAINER VAPOR VENT

The most significant vapor generator in an HPLC system is the waste

can, where solvents draining to the container may volatilize rapidly

as solvent entering the container forces vapor into the laboratory.

Activated carbon has excellent adsorptive properties for organic sol-

vents. With a Gas Chromatograph, a number of carbon types were

tested for vapor breakthrough under a flow of Acetonitrile vapor, one

of the more common solvents used in HPLC. After determining the

appropriate type, the carbon was similarly tested on other common

solvents. The breakthrough data published in this brochure is based

on use of 100% concentration of each solvent, at a flow rate of 1

mL per minute at S.T.P. (most analytical HPLCs run at 1-2 mL per

minute). Disposal of spent cartridges should be conducted in accor-

dance with local safety codes.

P U R C H A S E F R O M :

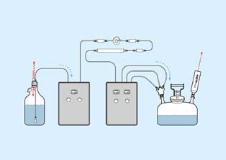

1: Solvent Reservoir A: Fluid Connections

2. Waste Container B: Air inlet (1) or vent (2

EXAMPLE OF A CLOSED SYSTEM HPLC

PUMP

DETECTOR

A

B

1

2

B

A

VapLock

TM

and VapCheck

TM

are Trademarks of Western Fluids Engineering & Mfg, LLC

Teflon

®

, Tefzel

®

, Viton

®

, and Delrin

®

are Trademarks of E.I. du Pont de Nemours and Company

Safety Eco Funnel

TM

is a trademark of CP Lab Safety

Kel-F

®

is a Registered Trademark of the 3M Company

PEEK

TM

polymer is a Trademark of Victrex PLC

Justrite

®

and Centura

TM

are Trademarks of Justrite Manufacturing

Nalgene

®

is a Trademark of Nalge Nunc International

Duran

®

is a Trademark of Schott AG

P R I C E S S U B J E C T T O C H ANG E W I T HOU T NO T I C E

For information regarding your local distributor, please contact:

+ 1 . 9 5 1 . 4 7 1 . 2 5 1 1 [ t e l ]

+ 1 . 9 5 1 . 4 7 1 . 2 1 0 7 [ f a x ]